EDF, Technocentre Project, France

Background

The decommissioning and mid-life refurbishment of EDF’s NPP fleet and Orano Georges Besse 1 plant will produce a highly significant amount of metallic waste originating mainly from end-of-life steam generators and pressurisers. EDF’s existing melting facilities cannot cater for such large components.

Solutions such as on-site decontamination and direct shipping to a VLLW disposal site of single-piece large components is not possible for EDF’s fleet (58 reactors, i.e., more than 300 steam generators) because of disposal space scarcity, treatment and disposal cost.

Challenge

In this context, EDF plans to create a large-scale melting facility capable of receiving large components while benefiting from the experience Cyclife France has gained in melting (as operator of Codolet incineration and melting plant, formerly known as Centraco) and Cyclife Sweden in melting (Studsvik Nuclear AB site, Nyköping).

Our proposal

Cyclife has been tasked by EDF to use its expertise during the basic design phase in the fields of radiation protection, zoning definition and HVAC preliminary studies and specifically on the assessment in terms of radiation protection impact of an alternative scenario considering no prior decontamination of the SGs bundles.

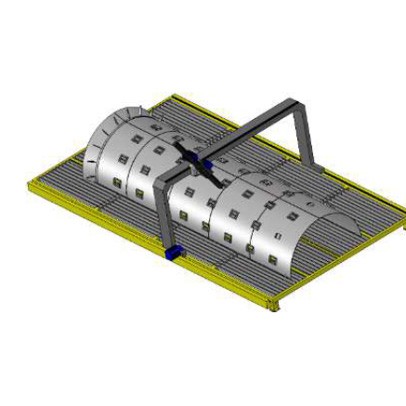

Cyclife brought also its experience in cutting tools selection for SG’s segmentation, by providing a list of cutting tests to be performed within Cyclife Sweden facilities.

Design to cost process implementation following the first version of the basic design.

Customer benefits

- Biological protection optimisation

- Update of the radiation zoning

End-results

- Comparative study with/without prior decontamination of the SGs in terms of ventilation, radiation protection, zoning

- 9 cutting tests proposed with various tools (diamond wire saw, oxy-fuel, shear) to fit each SG’s part cutting configuration

- Next step: Detailed design to be achieved by Cyclife Engineering