EDF Technical Operations - UTO, France

Background

EDF wanted to condition Ion Exchange Resins (IER) from the primary circuit of pressurised water reactors (PWR) in its Nuclear Power Plants (NPPs).

Given their radiological activity, it was difficult to move this waste. Cyclife France worked with EDF UTO to develop a mobile solution for treating IER directly on site.

Challenge

- Develop a concrete matrix for conditioning IER

- Design a unit able to treat waste directly on-site and to avoid transportation

- Develop a conditioning system that guarantees the long-term containment of IER for final disposal

- Be compliant with the requirements of the French National Radioactive Waste Management Agency (ANDRA)

Our proposal

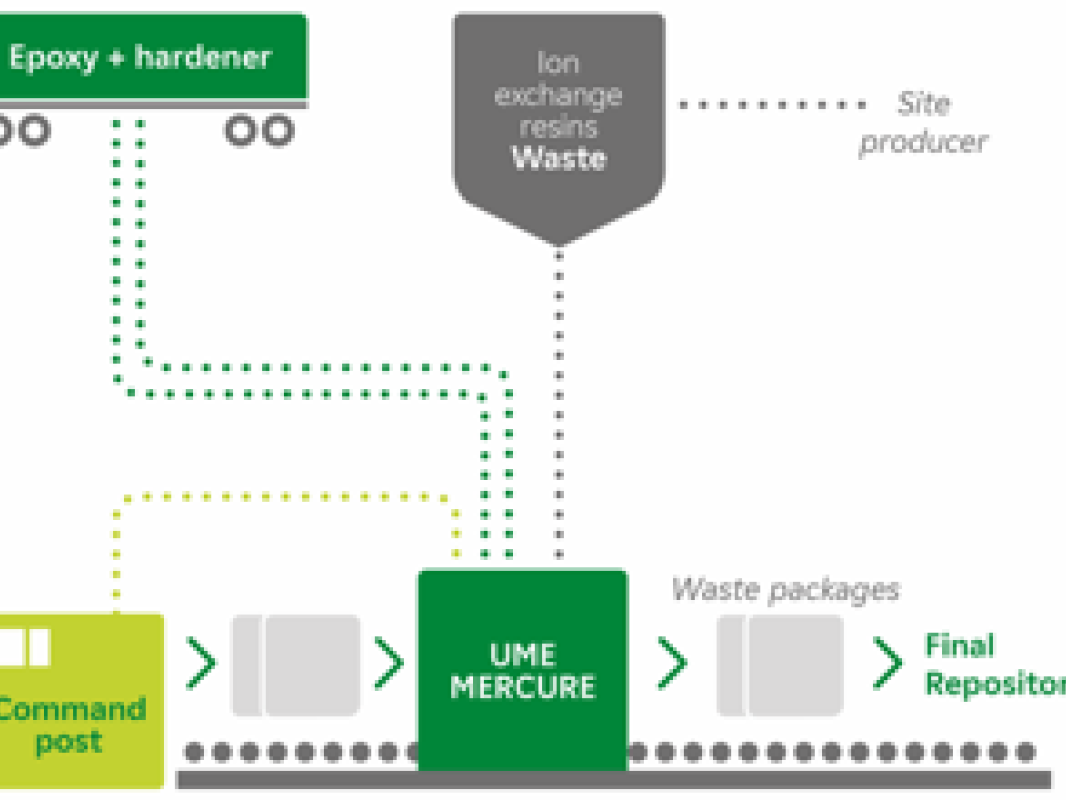

Cyclife France, in collaboration with EDF, has designed, developed and commissioned a Machine for Encapsulating Resins in Shells Using Epoxy Resin named “MERCURE mobile unit”.

The Mercure mobile unit consists of 7 parts that work together. The mobile coating unit, the main element, transfers and coats the REI in concrete shells to enable them to be transported to the final storage area in complete safety and security.

Key steps

- 1993: Beginning of studies

- 1996: Commissioning of the first MERCURE mobile unit

- 2002: Commissioning of the second MERCURE mobile unit

Key technical information

- Radiological criteria: total specific activity of βγ emitters < 13,500 GBq/m3

- Durable encapsulation matrix and packaging using an epoxy matrix approved for ‘300 years’ by ANDRA

- Packaging in a concrete container reinforced with integrated radiological protection

Customer benefits

- A turnkey service from waste collection to on-site packaging

- Machines that move directly from one site to another

- Dedicated, trained and reliable teams

- Treating IER throughout the operations to make valuable space on-site available

- Compliant packaged resins to be transported for final storage by the operator

Results

- Following the success a second machine was commissioned in 2002, to meet the growing demand

- 5,265 m3 of IER conditioned by the 2 machines between 1996 and 2023

- The 2 MERCURE mobile units can be used on all PWR NPPs in France

Machine for Encapsulating Resins in Shells Using Epoxy Resin named “MERCURE mobile unit"

MERCURE process

MERCURE mobile unit in operation on site

MERCURE mobile unit in operation on site

MERCURE mobile unit in operation on site