Magnox, Chapel Cross NPP, UK

Background

Top gas ducts transferred hot gas from the graphite core to the boilers (primary circuit).

- 820t: 4 reactors with 4 boilers/reactor

- Components de-planted and laid-down prior to contract

- Metallic components as surface-contaminated LLW. (Contamination up to 25,000 Bq/cm² / Doses rates up to 1.1 mSv/h /Dominating nuclides : Co-60, Cs-137, Pu-241, Sr-90)

- Elbows transported on road to the UK / RoRo ferry shipment to Sweden and finally road transport to site

- Gas duct assemblies transported and loaded to a chartered geared vessel for direct shipment to Cyclife Sweden site

Our proposal

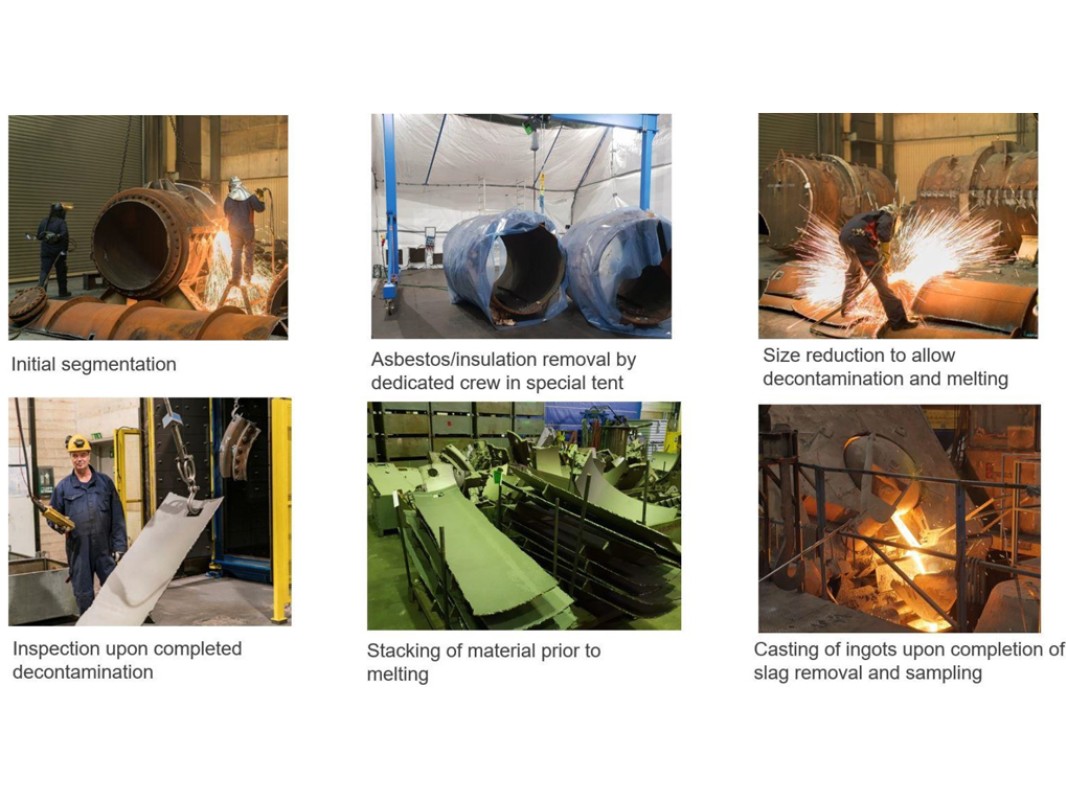

- Initial segmentation

- Asbestos/insulation removal by dedicated crew in special tent

- Size reduction to allow decontamination and melting

- Inspection upon completed decontamination

- Stacking of material prior to melting

- Casting of ingots upon completion of slag removal ans sampling

Transcript

- Initial segmentation

- Asbestos / insulation removal by dedicated crew in a special tent

- Size reduction to allow decontamination and melting

- Inspection upon completed decontamination

- Stacking of material prior to melting

- Casting of ingots upo, completion og slag removal ans sampling

Customer benefits

- Fast removal from site

- Proven and safe solution

- Low total cost

Results

- All gantry material met criteria for direct general clearance: i.e. without melting.

- 127 melt batches were conducted in total: 98.4% of the produced ingots became subject to clearance and 96.4% recycling rate in the melting process

- >90% total recycling rate, considering all material shipped for disassembly and treatment