Orano, The Hague - France

Background

In 2002, Orano notified Cyclife France of its need to take in charge and treat the solvent TBP used in its radioactive waste reprocessing plant at La Hague.

TBP degrades during its use and must be renewed regularly. With limited on-site storage and treatment capacity, it was necessary to develop a process to reduce the volume of this incinerable liquid low-level radioactive waste (LLW).

Challenge

- Demonstrate that Cyclife France is able to receive specific LLW at the Centraco facility:

- Upgrade Centraco's acceptance criteria to increase its capacity limit for receiving waste with an α content from 50Bq/g to 370Bq/g

- Receive approval and compliance from the French Nuclear Safety Authority (ASN) for the changes required to the installation and the repository

- Carry out and successfully complete the design, works and commissioning phases

- Receive the TBP tank and incinerate its contents in complete safety and reliability

- Create a new treatment route for this waste

Our Proposal

In order to receive and incinerate TBP solvent tanks from the Orano site, Cyclife France proceeded as follows:

- draw up a regulatory file with the ASN to carry out changes of the Centraco site and on the radiological activity to α in its standard level

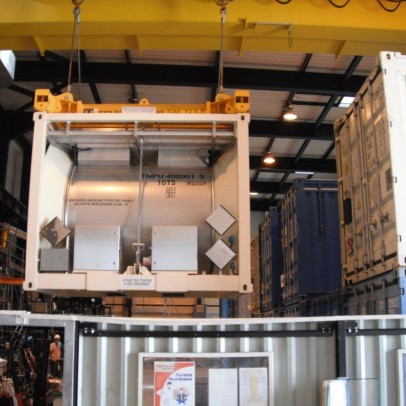

- amend its facilities, mainly at the liquid waste reception area by:

- creating a dedicated unloading station with an enclosure enabling samples to be taken

- installing pumps and piping circuits to the storage tanks

- establish incineration protocols (flow rate, filter clogging monitoring, etc.)

Key steps:

- Incineration testing phases in 2002 and 2006

- Preliminary design and detailed design studies began in 2008

- ASN authorisation in June 2012

- Start of works in 2013

- Industrial commissioning in 2015

Technical data:

- Waste handling with an α activity of up to 370Bq/g

- Unloading into a sealed environment of a 5m3 tank (ventilated docking hood)

Votre navigateur ne prend pas en compte le javascript.

Pour vous permettre d'accéder à l'information, nous vous proposons de consulter la vidéo Waste volume reduction by Incineration according to Cyclife dans un nouvel onglet.

Customer Benefits

- Development of an industrial process for the treatment of TBP

- Removal of tankers on a regular basis

- Cost saving in avoiding extensive on-site storage

Results

Evacuation and treatment capacity of up to 12 tanks per year