Cavendish Nuclear, Magnox Berkeley, UK

Background

As part of the Magnox ILW Management Programme, ILW at Berkeley currently stored in the Active Waste Vaults needed to be retrieved and transferred to Ductile Cast Iron Container (DCIC)

Cyclife Aquila Nuclear took ownership of the concept scheme from Cavendish Nuclear, producing 3D models and detail manufacturing drawings along with supporting substantiation and justification documentation

Challenge

Design needed to be carefully considered as the processing skid was to be operated remotely whilst processing and all fault scenarios considered.

Fully interlocked and guarded for operator maintenance activities

Our proposal

Key technical data:

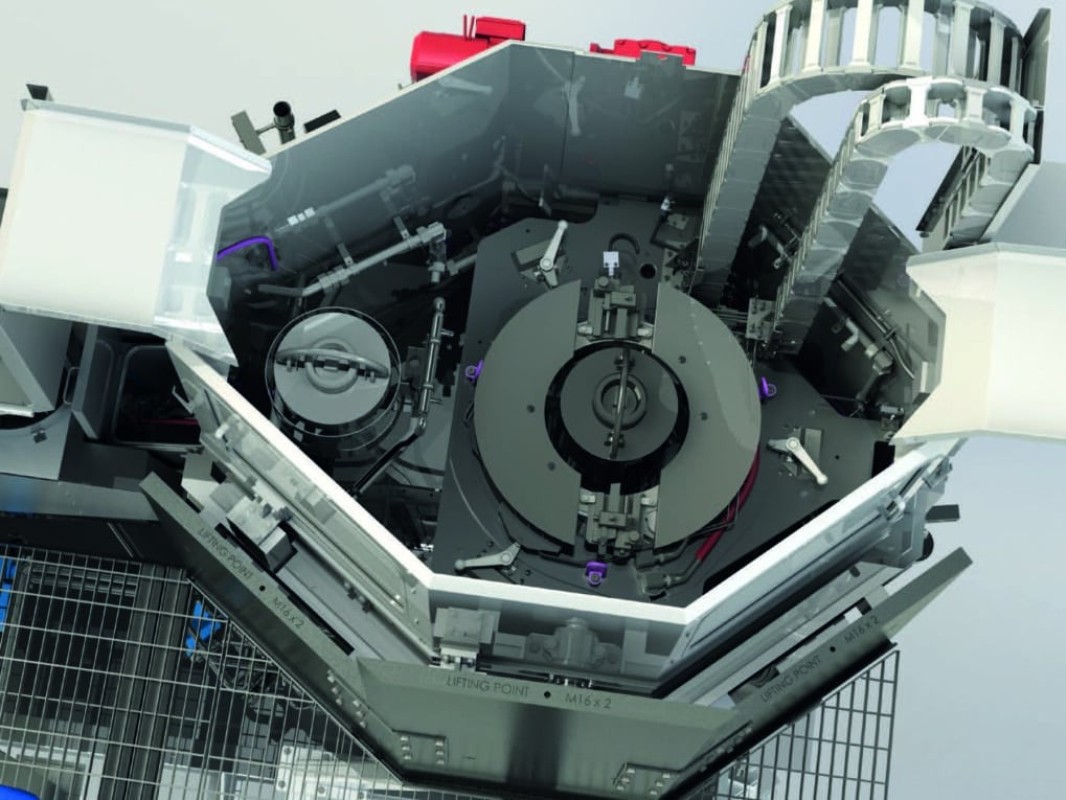

- Can cutting and rotating table

- Sludge auger

- Sludge pipework included various manual and electrically actuated valves for processing the sludge or valves for various blockage / fault scenarios

- Two wash systems that allowed for cleaning of cans and resuspension of the sludge within the Hopper

- Macerator and associated pipework

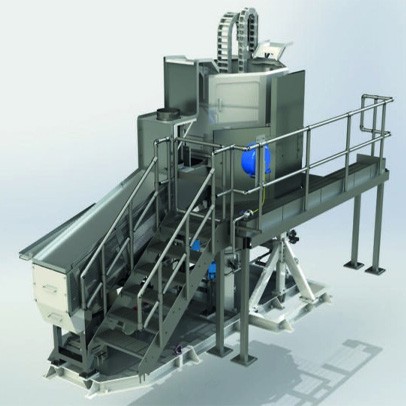

- Designed as a skid for ease of installation

Customer benefits

- Working closely with Cavendish Nuclear to develop design to ensure compliance

- Process refined and improved during commissioning

- Extensive factory trials and fault scenarios to ensure the equipment met the functional and lifetime requirements for processing of the sludge cans.

Results

Cyclife Aquila Nuclear completed the project to specification and on time despite a challenging Magnox programme