Healthcare, UK

The customer required the design and build of two Waste Posting Facilities (WPF) to safely and efficiently handle decommissioning waste from their plant while complying with strict regulations and ensuring maximum safety.

- 4 bullet points on main services involved

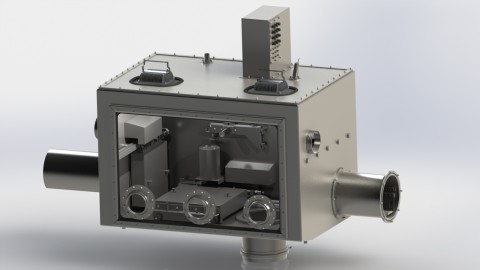

- Design and manufacture of fully shielded containment systems

- Creation of transfer tunnels with safety interlocks

- Development of a VIP Can docking system

- Integration of gamma monitors and ventilation systems

Challenge

The main challenge was reducing containment category classification and associated costs while maintaining high safety standards. Collaborating with the user's technical team to create a pragmatic functional specification was crucial to achieving this.

Our proposal

- Key milestones: Development of the 3D concept model for design and operating features. Compliance with legislations and safety standards. Integration of gamma monitors and ventilation systems.

- Key technical data: Stainless steel containment with 100mm lead shielding. Transfer tunnels with sliding trays and interlocked shielding doors. VIP Can docking port with shielded door. AMP-100 gamma monitor and Canberra G64 area gamma monitors.

Customer benefits

- Cost and time reduction through containment category classification reduction

- Efficient waste handling and quantification

Results

- Reduced project costs and timescales

- Enhanced safety and control in decommissioning waste handling